Ecological material production plant

The use of recycled granule and powder has several application sectors.

Coloring plant for rubber granules

Green Crumb Tyres

The use of recycled granule and powder has several application sectors.

But in the last years, the consume of rubber recycled products has taken the upper hand in the employment for fields of synthetic grass.

Since the year 2000, it has been undertaken more and more advanced innovations for the granules production, which make them to have perfect requirement, both granulometric and elastomeric.

No less, it has been the innovation in the colouring of the granule called in Italian “nobilitatura” (painting). It consists of a chemical process where the granule is covered from a special coat of colour, making to it take several type of colour.

It is a very important and appreciated goal, even from other sectors of the employment of the recycled rubber granules, which has given to the secondary raw material coming from the used tyres grinding, the synonym of “end product”.

Thanks to our experience, both productive and of machines building, we are able to offer semiautomatic and automatic solutions for the rubber granules colouring, up to modular productions of 1200 kg/h, assuring the greatest operating reliability.

The installed electrical power is of 20 kW, without wear and maintenance.

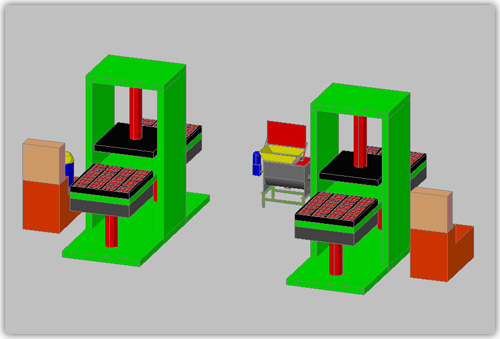

Press work plant for antishok floor

Although the incentive to the building of used tyres recycling plants represents a very good business chance, the same is the possibility to can satisfy an ecological use of the recycled product.

TIRES S.p.A. besides to innovate its recovery lines, studies and acts next to engineering studies for applications in the urban use, thanks to elastomeric property of the recycled rubber granules and powders.

The company has put right a simple system of cool pressing from which you obtain anti-shock floors, which get a very good and fast remuneration on the market.

The plant allows to stamp ecological tiles composed of rubber mixes coming from the recovery of used tyres, and ties with polyurethane resin.

They are produced with the using of pressing technique and processed to colouring through the using of several types of coloured pigments.

Anti-shock floors produced by our plant design, can be certified for the critical height of fall (HIC) on the several thickness of realizing, according to the law EN 1177.

Applications: Recycled rubber anti-shock floors was opportunely studied for applications in the urban furnishings to eliminate the danger in the areas where usually one runs, one jumps, one plays, like playgrounds, terraces, pool, bicycle path, etc.

The principal characteristic is to eliminate the danger of slithering and to cushion the fall shock. Moreover, it has been created and projected to resist to the atmospheric agents and to the wear, with some characteristics that favour the water drainage.

UNI EN 1177 Coverings of surfaces with impact absorption.

Such a law is the official Italian version of European EN 1177 approved by (CEN) European Committee for Standardization, on August 1997.

It sets the least requirements for any type of investment of play surface for children, in order to cushion the fall impact.

During the playing, children can suffer wound for accidental causes. Injuries to the head represent the most critical conditions, so CEN drew a law which classify absorber materials to use like covering in the play surfaces, in order to decrease the probabilities of injuries to the head.

The law UNI EN 1177 so, orders the factors to have in respect in the choice of the type of the floor for playgrounds and it gives a test case to set the damping impact.

The final result of a such test specify the minimum falling height for every single type of covering, indicating the maximum efficacy limit in the decreasing of the possible injuries coming from falling, during the normal use of the plays complying with the rule UNI EN 1176.